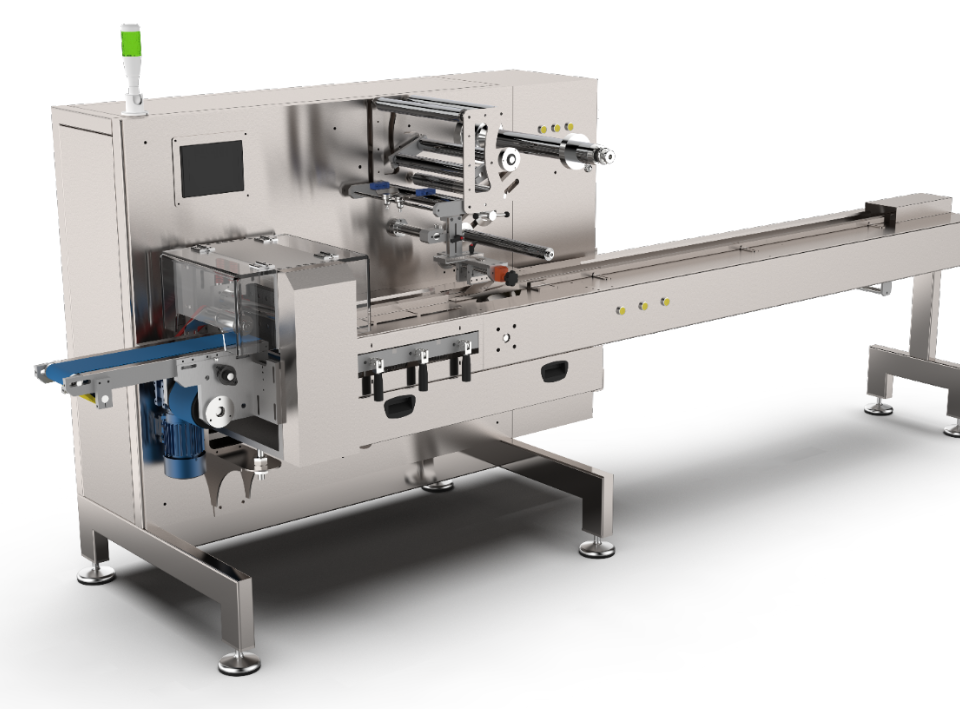

Our Activo 1000 mobile jaw packaging machine model has automatic bobbin transfer and takes the bobbin movement from the fourth servo motor.

The frame and the conveyor structure of the machine are designed and manufactured in stainless steel.

The heavy body of the machine prevents vibrations that occur at high speeds.

With this stable feature of our movable jaw, it can work at high capacity without any problem.

It offers easy maintenance thanks to its specially designed body structure.

There is no need for air consumption.

There is no stroke limitation per unit of time connected to the pneumatic system.

In addition to the blade in the pneumatic system, especially the instantaneous forward and backward operation of the jaw causes vibration, our machine offers smooth operation through the servo eccentric system.

The servo-driven eccentric jaw speed is the same as the spool speed during gluing, and it offers the ability to work at high capacity by working relatively fast and slowly on short and long products.

The eccentrically working upper and lower jaws are aligned at four points, thus preventing possible jaw leakage.

By minimizing the tape-jaw exit distance, it is possible to work with short products when needed.

Equivalent pneumatic jaws max. 50 packs / min. Our machine, on the other hand, offers only one product in the packaging depending on the type and size of the product and the range of max. 80-100 bundles / min on 250 mm. working speed.

Jaw, disc, reel and conveyor movements are provided by four independent servo drives.

Parameters belonging to different customer products are written to memory with the recipe system.

The recipe system provides the operator with both quick product changes and ease of use. (thus minimizing human induced operator errors)

Application Images