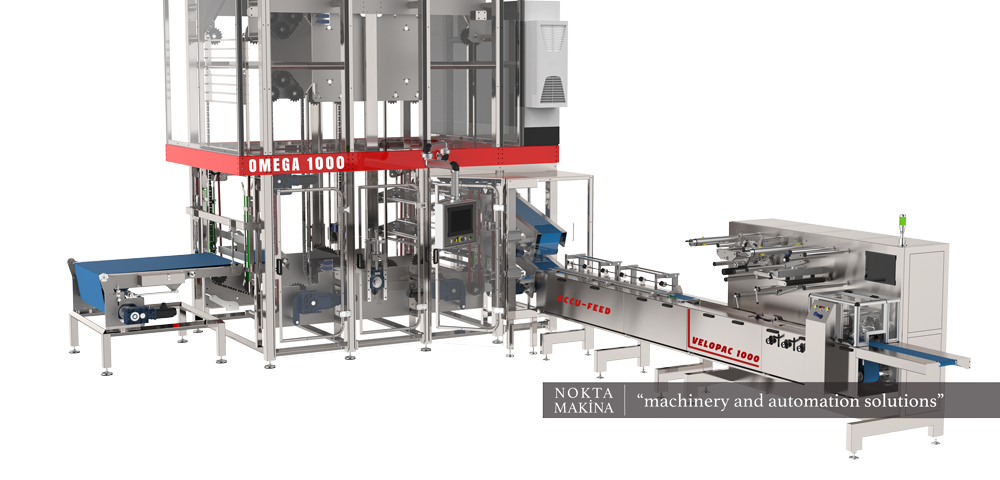

With the new generation of VSS “Vertical Stacking System” namely the vertical storage and supply system, Omega 1000 is designed to protect stabilization and save energy in mass production.

In mass production, properly planned power systems minimize product loss, protect product quality and save energy.

Unlike other feeding systems, the Omega 1000 dispensing system from Nokta Makina ensures that excess production is fed regularly without clumping during packing. Omega 1000 prevents product loss caused by production interruptions and ensures that the process between production and packaging continues without interruption. The Omega 1000 placed in front of the packaging machines maintains the product flow stable for 10 to 15 minutes depending on the capacity of the product.

In accordance with European Omega 1000 occupational safety standards, all moving parts are designed with transparent panels.

The shelving systems have a hygienic structure with a special alloy coating.

There is a wide range of products such as chocolate, wafers and cakes in the product line that can be used.

The Omega 1000 machine includes entry and exit belts and an access control system.

In addition to the ability of the Omega 1000 distribution system to hold products, it also has a distribution task between production and packaging lines. In this way, the problems related to the production chain are eliminated.

The Omega 1000 system consists of 11 servomotors and has easy operation and diagnostic functions on the touch screen.

Dual outlet packaging feed option is available depending on line layout and capacity requirements.