- It consists of an electrical consumption of 25 Kw (400 V, 50 – 60 Hz, 3 phases) in each

- Each two-line machine has at least 13 servomotors.

- It is designed to perform all settings and production applications via the screen as well as easy access via the touch screen.

- Communication with the controller HMI and drivers based on high speed Ethernet technology is established.

- All parts are of solid construction.

- It is a coupled motor based on hybrid cable connection technology that provides high speed processing and real time motor diagnostics.

- The system has remote access to all components to reduce maintenance time and costs.

- The tension of the package can be controlled by an independent coil servo motor and an electronic tension sensor.

- The system check cycle for production accuracy is less than 1 millisecond.

- Settings and adaptations for 1000 different products can be saved in the recipe list.

- It consists of fast response PID controlled heaters for the jaw and specially designed aluminum disc resistors.

- Real-time machine status, warning, alarm and fault notifications are available.

- Parcel cutting can be performed with a servo motor and a print mark sensor.

- The conveyor belt, grip, disc and cutting jaws are servo-motorized.

- It has special functions for easy installation and use.

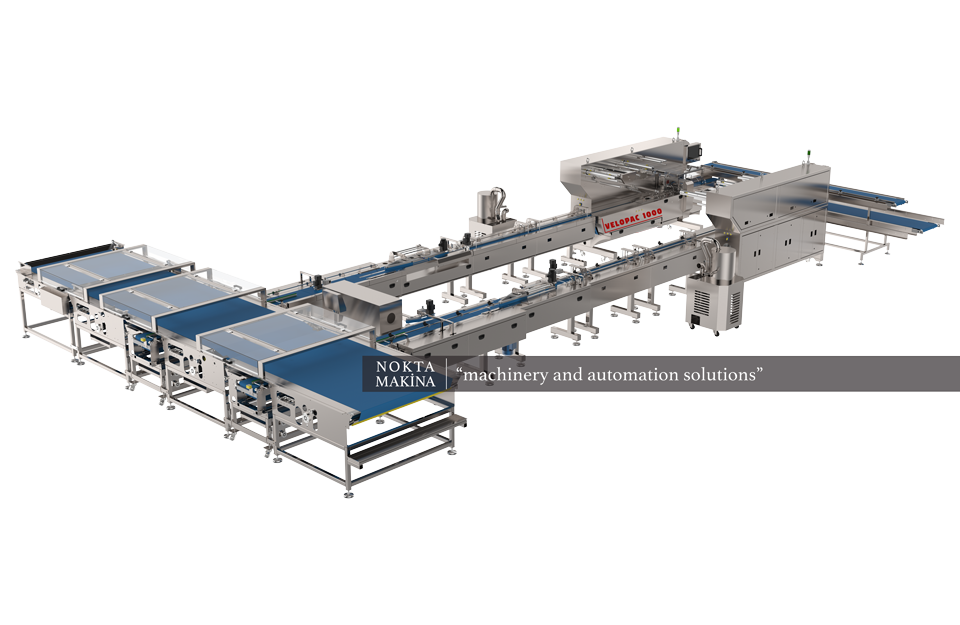

- The robust stainless steel machine body meets international food industry standards.

- The jaw safety is supplied with a key and a special cover.

- It has the feature of continuous automatic spool reel change and point position compensation for up to 3 products.

- The mechanical reel is controlled by the edges.

- It has a pneumatic coil clutch system.

- Correct jaw adjustment can be achieved with pairs of compression springs and ground jaw bodies.

- It consists of three sealed discs made of special steel which offers abrasion resistance.

- All movements can be transmitted by the planetary gearboxes without any gaps.